WASTECARE

Textiles So Good, Even the Waste From Production Is Certified as Skincare

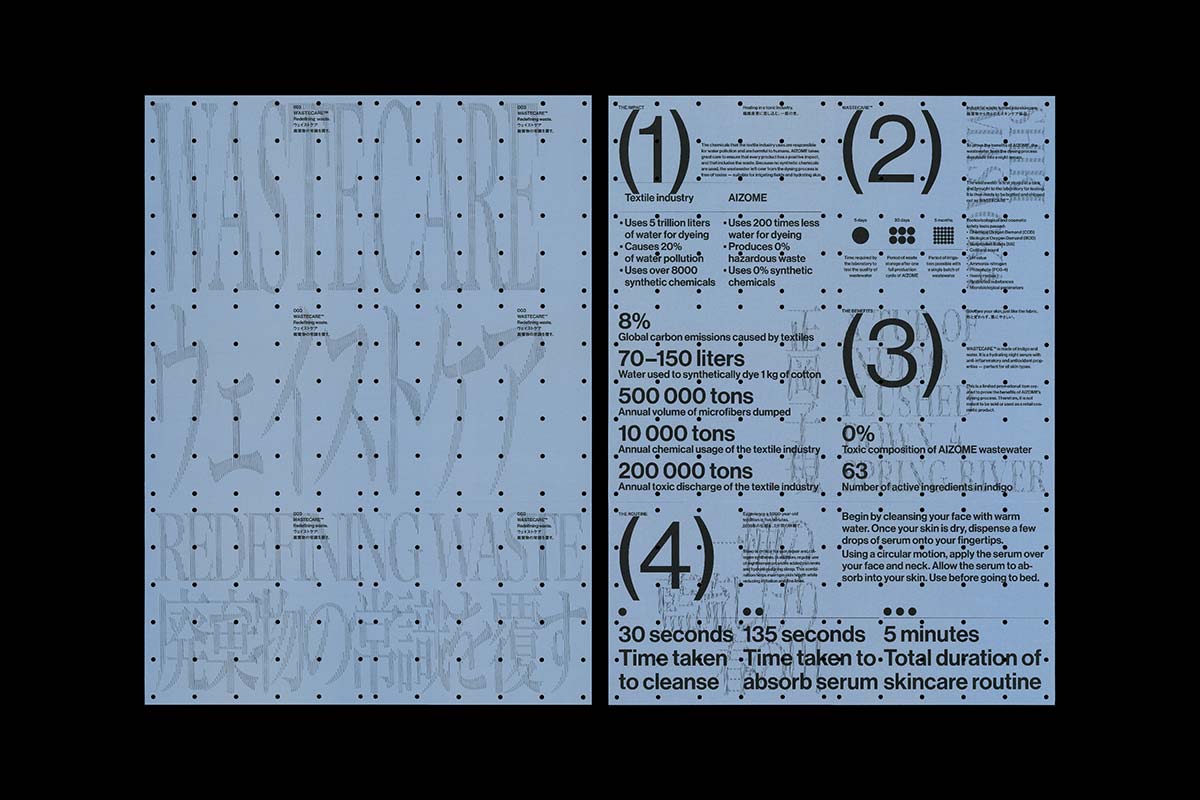

Textile producer AIZOME’s innovative ULTRA dyeing method not only produces textiles that are healthy but also waste that’s healthy, which they are now promoting as the skincare product WASTECARE.

Japanese-German textile startup AIZOME in partnership with Serviceplan Innovation launches WASTECARE, a premium skincare product that is wastewater from their textile dyeing factory. Because the AIZOME ULTRA method only uses plants, water, and ultrasound instead of synthetic chemicals, the wastewater, like the textiles, has natural health benefits, such as anti-inflammation, pain-relief, and skin rejuvenation. WASTECARE is being sent out to key opinion leaders in the fashion and textile industries to spotlight the damage caused on the environment and health, while also providing an innovative solution.

Since not only the product itself has an exciting story, but we at Slanted also consider the design of the packaging very exciting, we had the opportunity to ask a few questions to designer Han Gao from Workbyworks & Serviceplan Innovation’s Art director duo Rohil Borole, Kai West Schlosser:

Are there special requirements for a packaging design if it is to be sustainable? Which materials were a consideration for this?

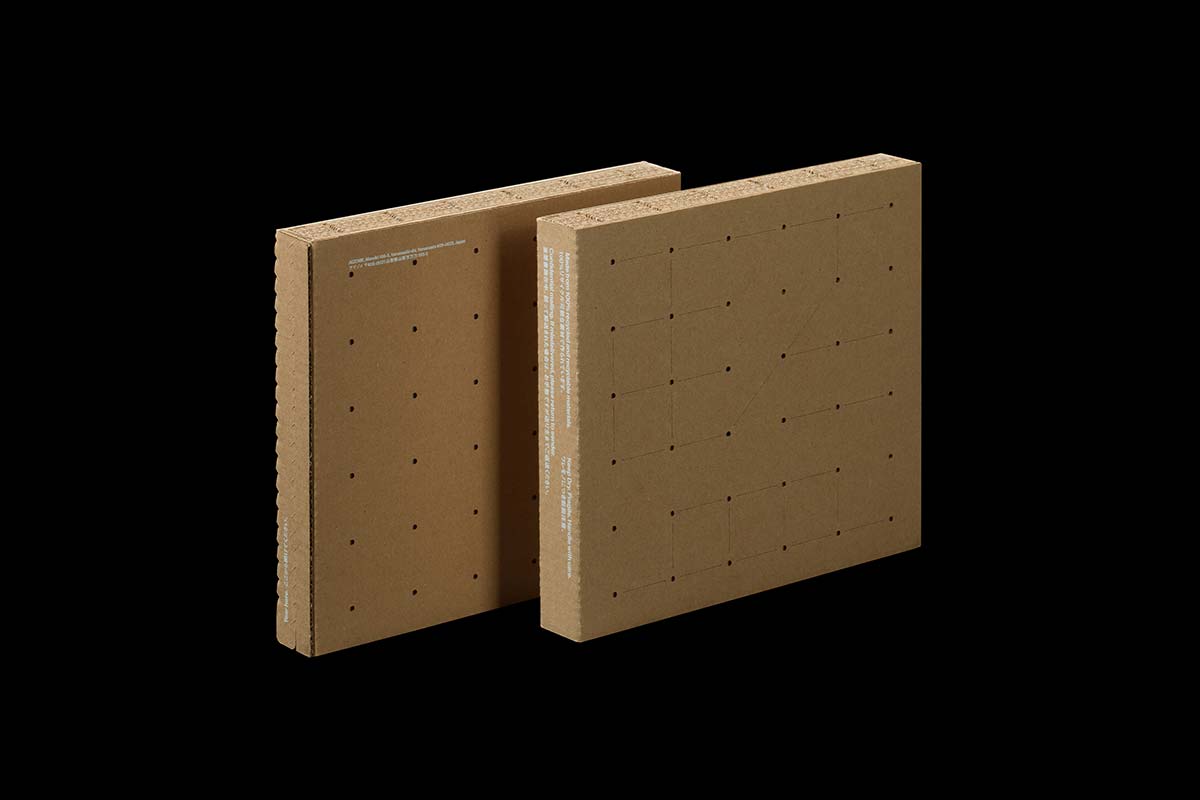

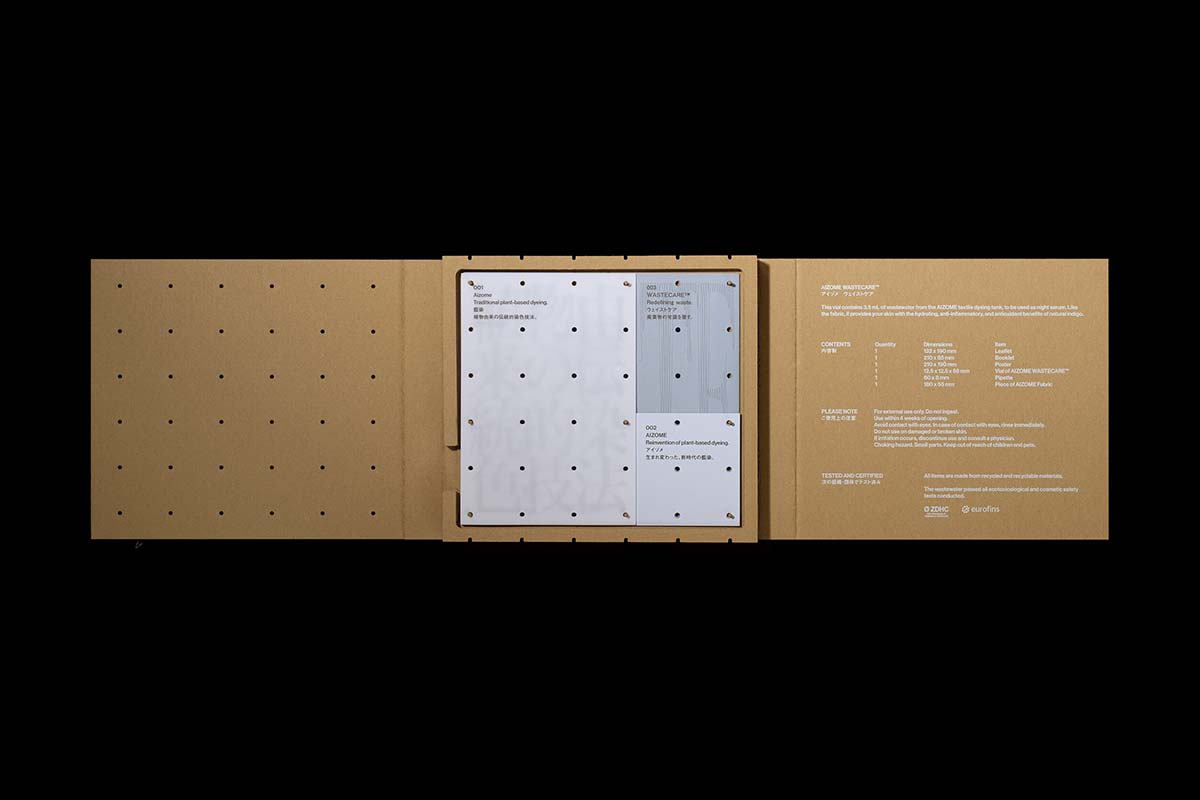

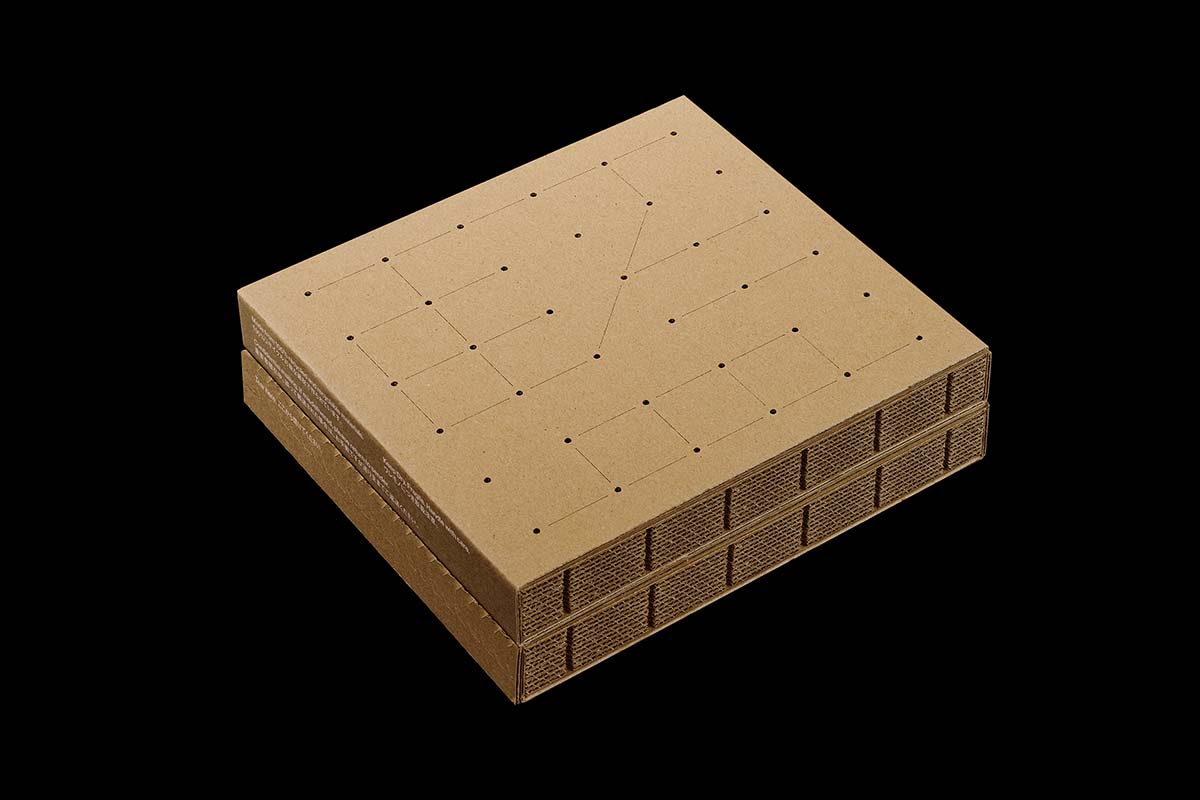

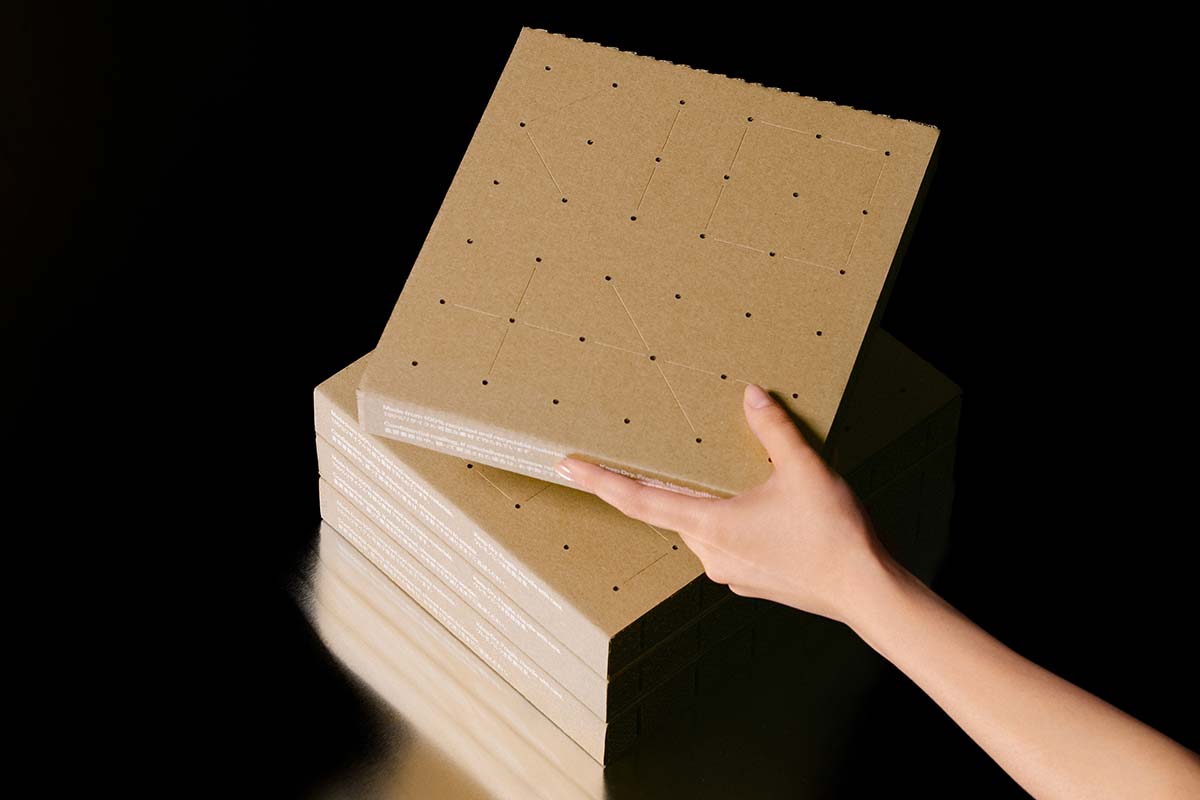

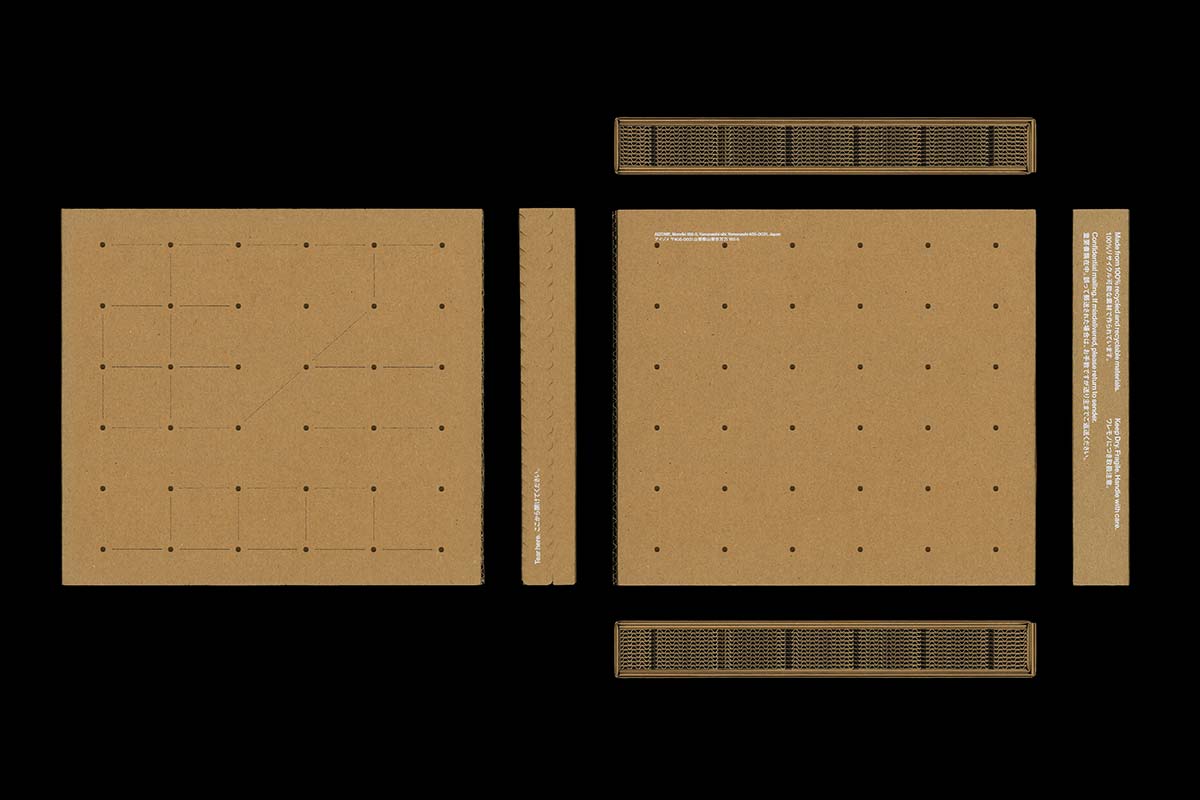

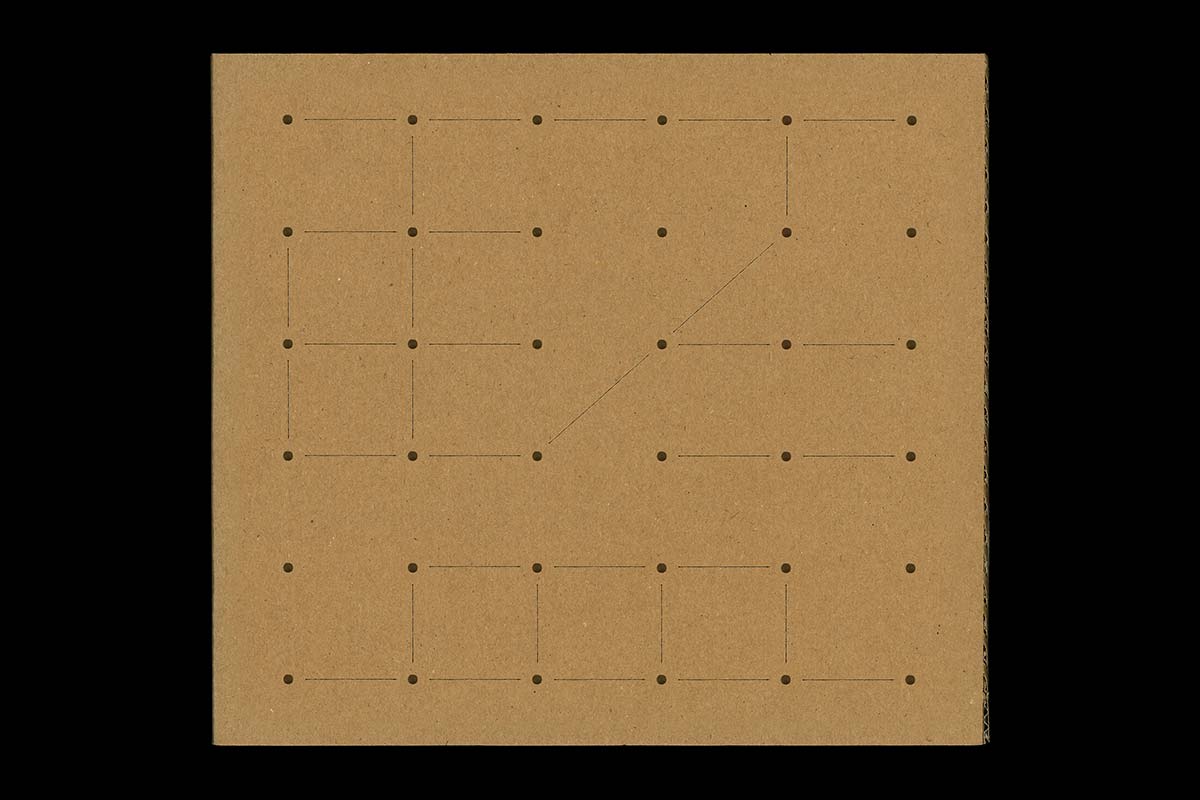

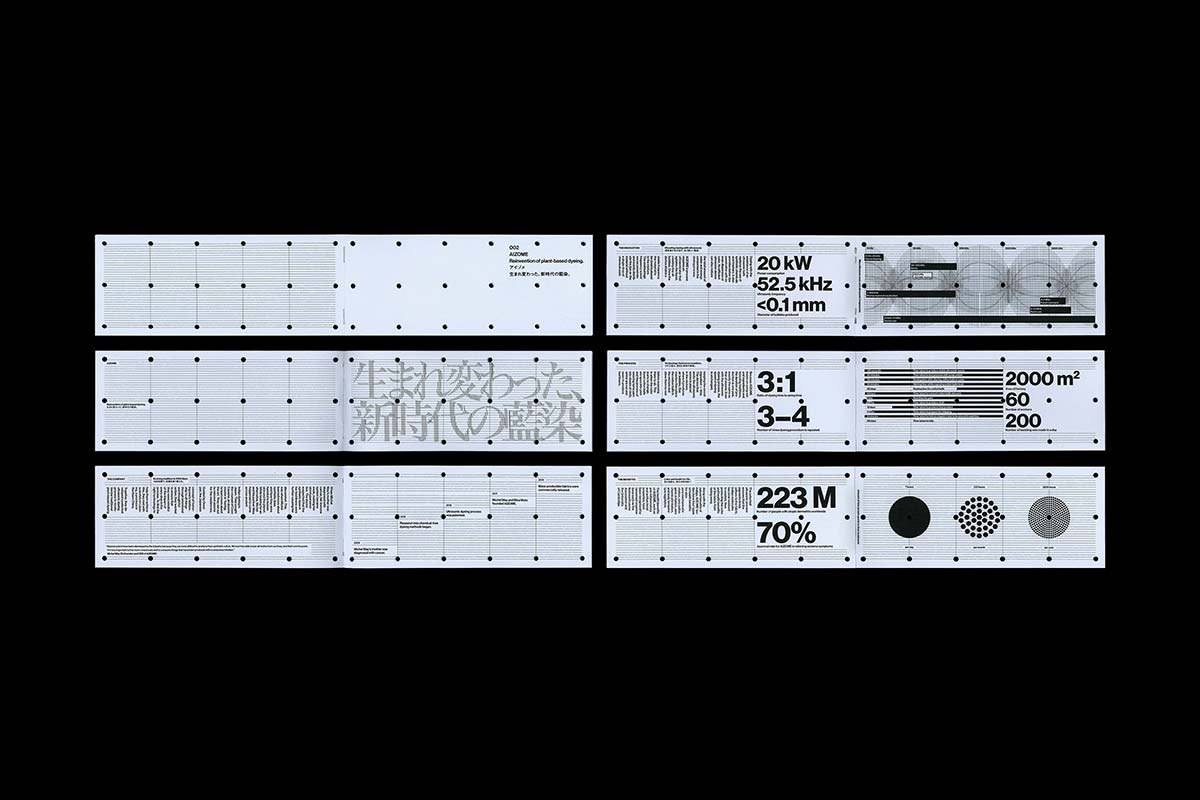

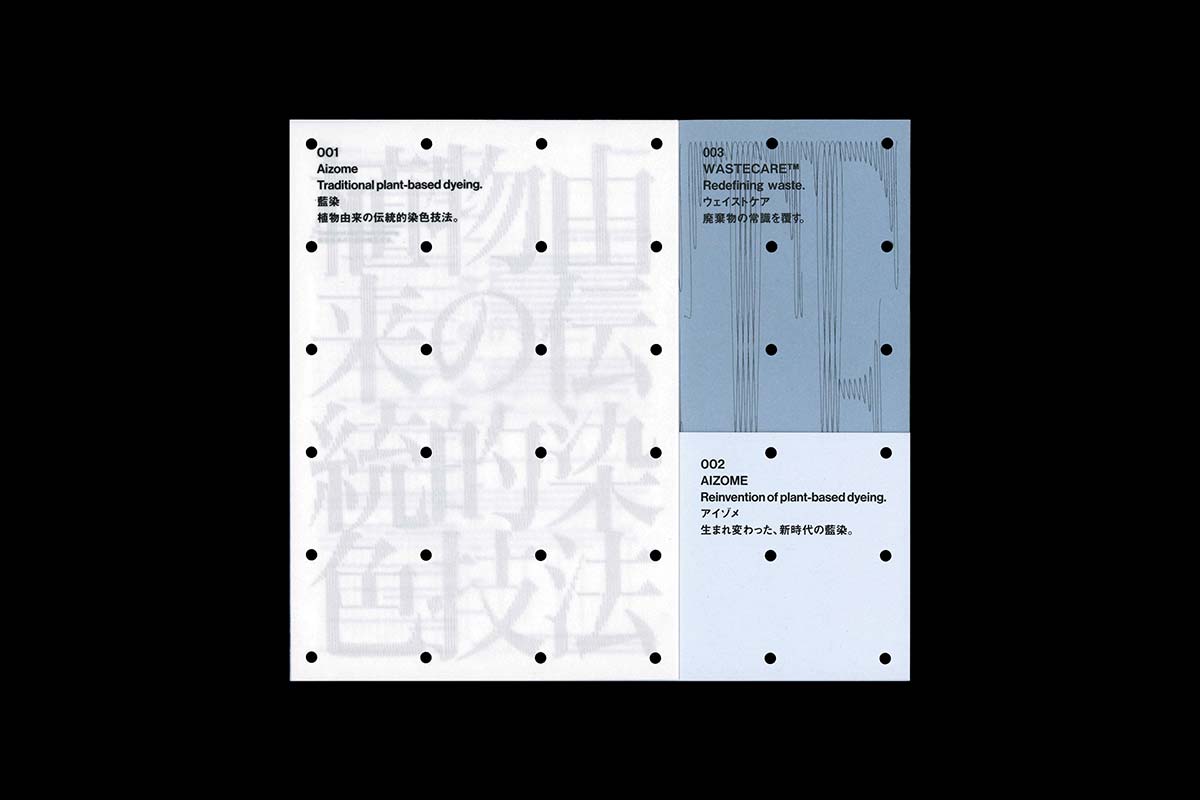

This is a product promoting a 100% chemical free dyeing method developed by a sustainable textile company, so it was crucial to minimize our footprint. The identity we developed is in the realm of luxury products but unlike the ones on the market, we do not make use of unnecessary packing materials. The entire box was designed such that it can be mailed out without an extra shipping box. Working closely with an industrial designer, we reduced material wastage in the assembly of the box. It follows a six-by-six grid pin registry, upon which all the sheets and trays are stacked. It was crucial for everything used to be recycled and recyclable. In creating this packaging, we wanted every aspect to reflect the company’s core belief and their technology.

How far did the consistency and color of the product inspire you to design the packaging?

The dyeing process was a predominant source of inspiration. In the first step, the dye itself is brown. Once the cotton balls are dipped and then exposed in air, oxidation causes the color change to blue.

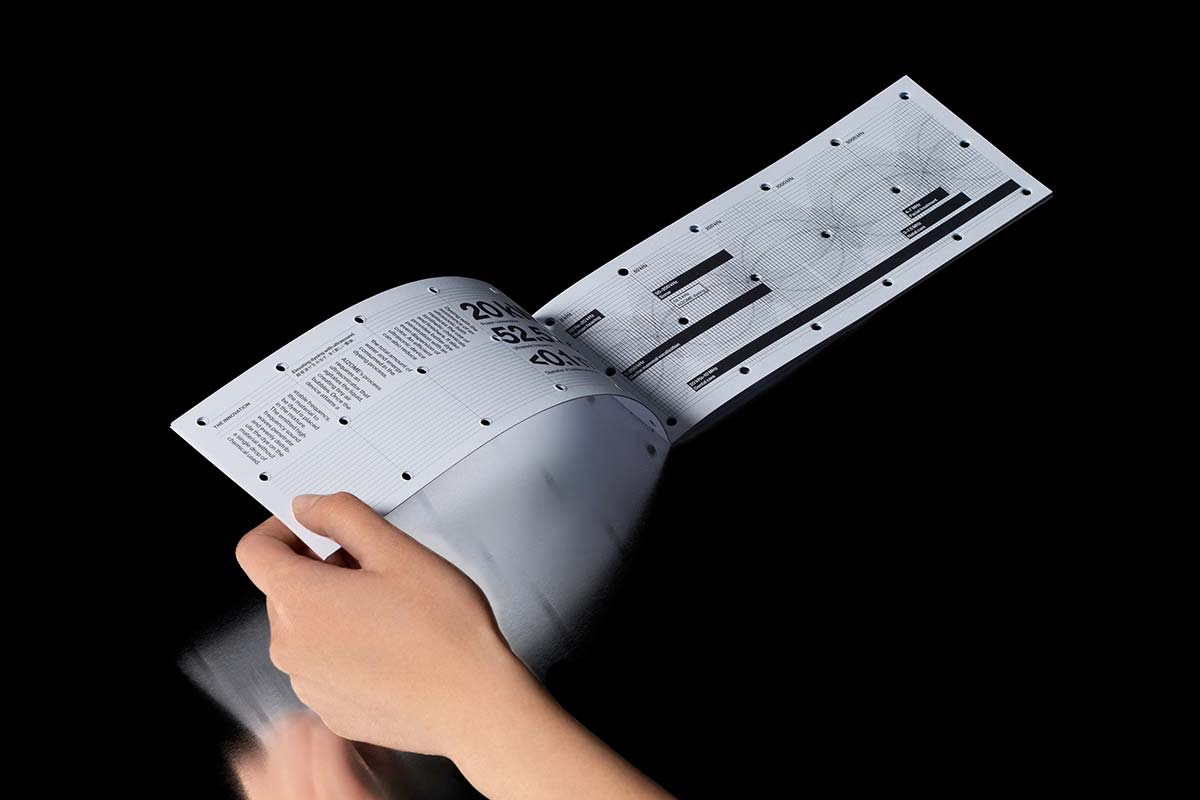

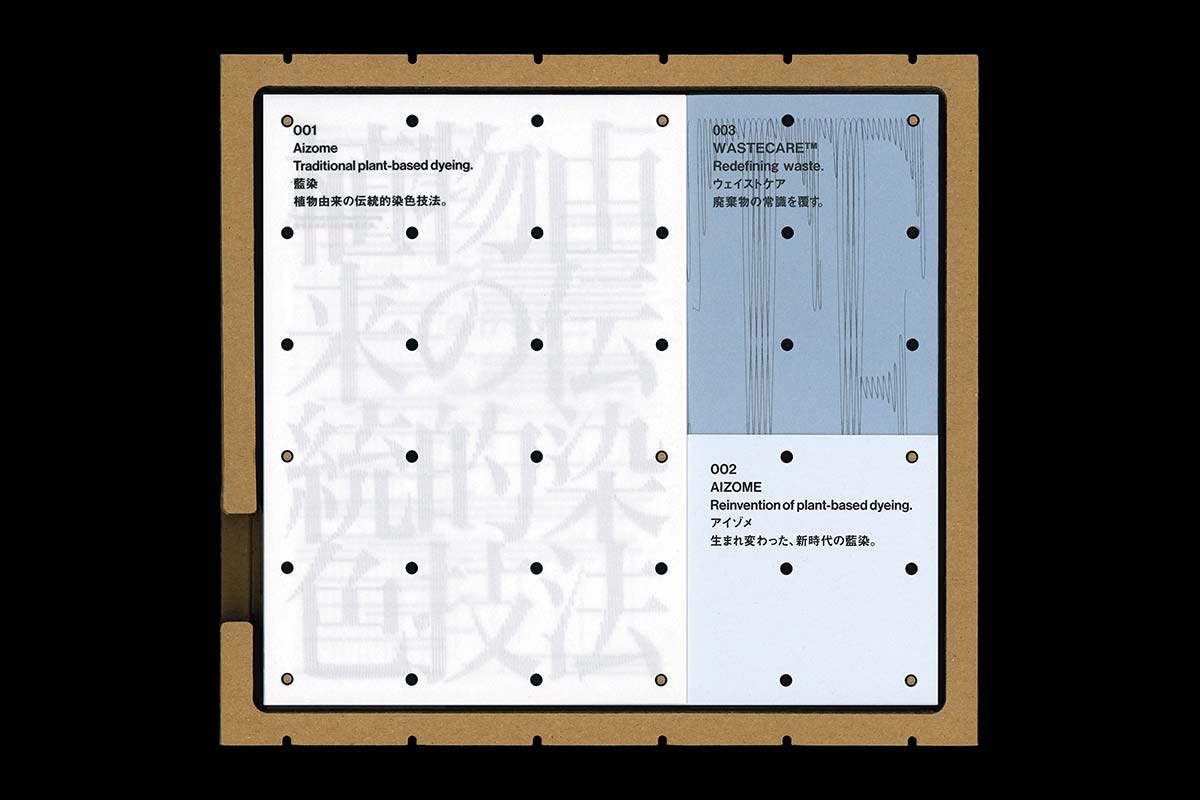

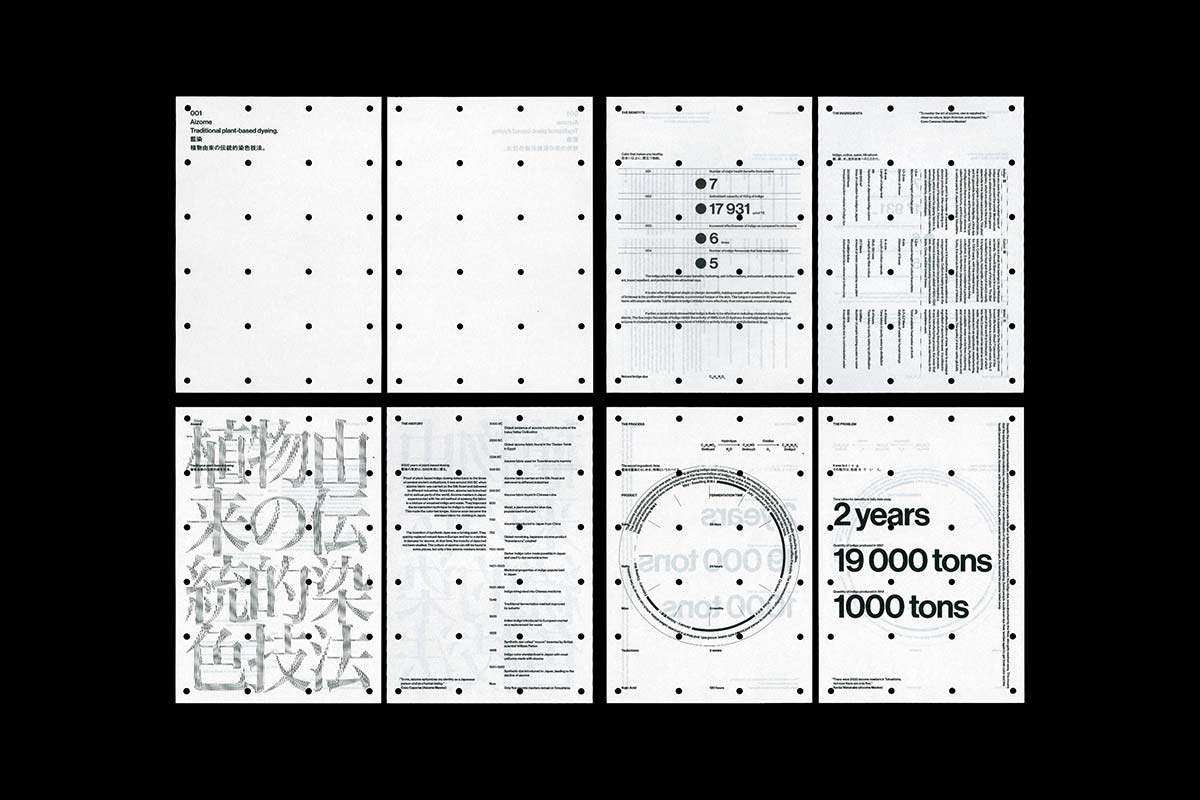

In our printed editorial, you see the color intensify from one section to another just like the cotton balls change color upon repeated dyeing. As you unfold these sheets, you reach the final layer which is a juxtaposition of the product and the byproduct of the process—wastewater serum and a piece of AIZOME fabric. The fabric is much brighter, and the wastewater is muted, but through the skincare routine we show how both have value.

The wastewater is unfiltered in that it still has tiny indigo particles suspended in the body. The brownish tint is a lighter version of the original vat of dye. You can also see that the usage of color in the packaging is earthy like in the very first layer of the packaging: the recycled cardboard, reinforcing the idea that all things start from nature. It can also be described as neutral; it does not boast or bias the user.

Was it a challenge to design a bilingual package and find the right typeface for it?

It may have seemed like a challenge at first but we’re a small team of international creatives and two of our colleagues are Japanese. So is the co-founder of AIZOME. We were surrounded with inspiration, and this truly helped mold the story of the product. With their support we could ensure that the English translation of Japanese quotes and haikus had the same depth as the original content.

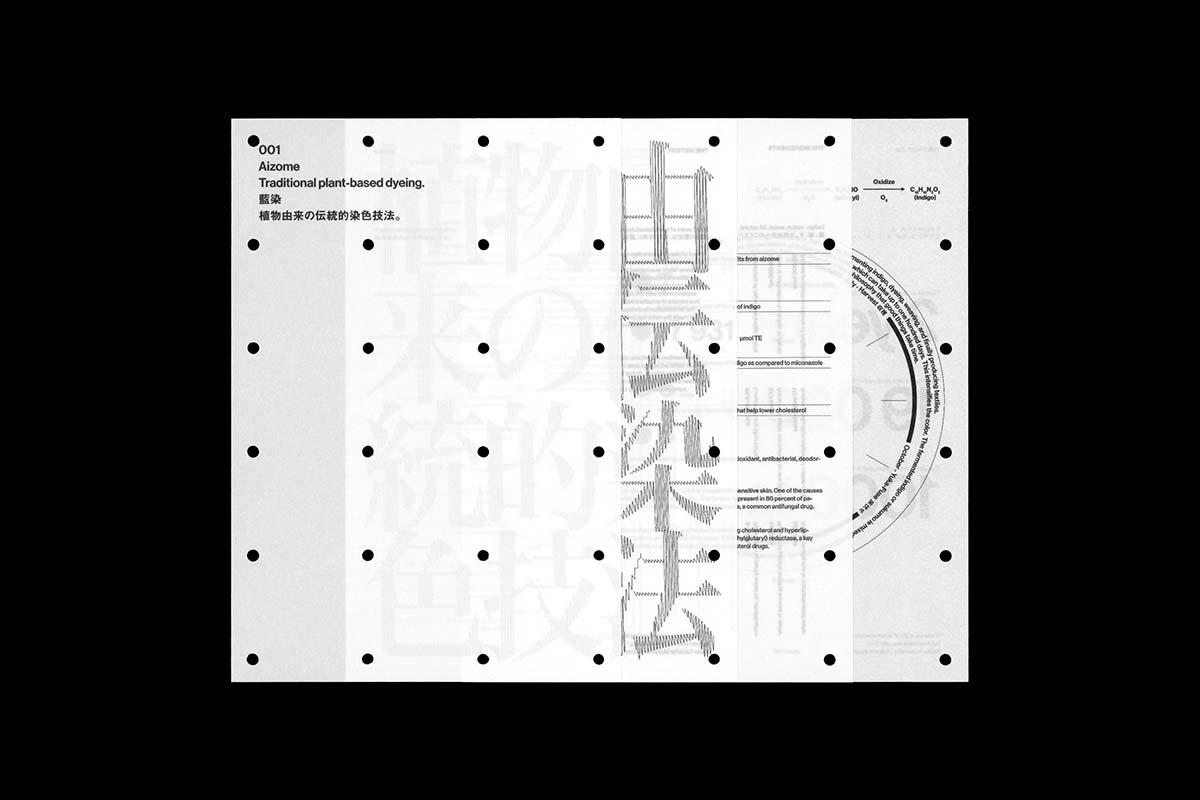

Regarding typography, we use three different typefaces: Neue Haas Grotesk for English text, paired with Midashi Gothic Pro MB31 for Japanese text—two timeless typefaces, matching AIZOME’s reinvention of traditional aizome dyeing.

For titles, we created our own, custom Ultra One type. We used the traditional Mincho type Hiragino Mincho Pro W6 as a base for this to reflect the rich history of the ancient Japanese dyeing tradition. We then used p5js to generate frequency waves on top, which represent ultrasound, which is the core of AIZOME’s innovative dyeing technology.

From the press text: According to the UN, the textile industry is the second largest water polluter, using over 1,500 synthetic chemicals in production. These chemicals not only cause pollution but also harm workers and wearers. In most dermatitis cases, the reaction is triggered by dye chemicals. Traditional plant-based dyeing lacks longevity for mass production. AIZOME ULTRA offers a solution by using ultrasonic dyeing to bind plant molecules to fibers, resulting in lasting color and health benefits. Medicinal plants like indigo provide anti-inflammatory properties, rubia helps alleviate menstrual pain, and turmeric acts as an antioxidant. The National Eczema Association recognizes AIZOME’s benefits for sensitive skin. A study with the University of Cambridge demonstrated indigo leaf's healing properties for skin injuries.

To differentiate themselves in the textile industry, AIZOME introduced WASTECARE, a skincare product made from tested and certified industrial wastewater. The packaging, designed in collaboration with Workbyworks Studio, offers an intimate unboxing experience and combines practicality with aesthetics. It features layers of cardboard for protection during shipping and promotes recycling. Each unboxing stage reveals AIZOME’s story through data visualization, fabric, and the face serum.